Polishing of

Specimens Services

The preparation of specimens (samples machining) is the first step in performing destructive and fatigue tests on metal materials. Tests are performed on standardized specimens in a way which reflects the level of stress occurring in real elements. For this reason the proper preparation of specimens is crucial, not only in terms of their geometric dimensions and surface roughness but also in terms of the residual stress level.

Our company offers the expertise in getting the finest results in polishing and low stress grinding of various specimens.

We offer:

– longitudinal low stress grinding of specimens made of various materials and hardness with the use of different types of sandpaper,

– polishing to individual specification. The final surface roughness can vary between 8 and 12 Ra (0.2 – 0.3 μm) – lower measures are possible.

The polishing process is performed automatically and is possible according to follows the customer’s requirements and international standards – ASTM E466, ASTM E606, EN 6072, NADCAP.

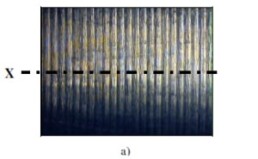

The surface of the measuring part specimen after precision turning (magnification 200x)

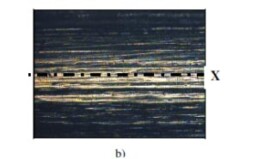

The surface of the measuring part specimen after longitudinal polishing (magnification 200x)